Reception Unit's visit to Derwent Recycling

All the

recycled paper from homes, schools and offices is recycled and made into

'Charmin' toilet roll.

Other cardboard is recycled and banded together. It is then loaded into a

container on the back of a truck and sent on a ship to China to be manufactured

into new cardboard sheet. This cardboard sheet is then used in the manufacture

of Easter egg packaging and toy packaging, amongst other things.

Plastic windows are recycled to be made into new ones.

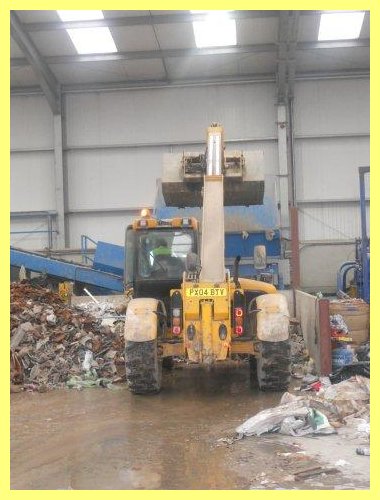

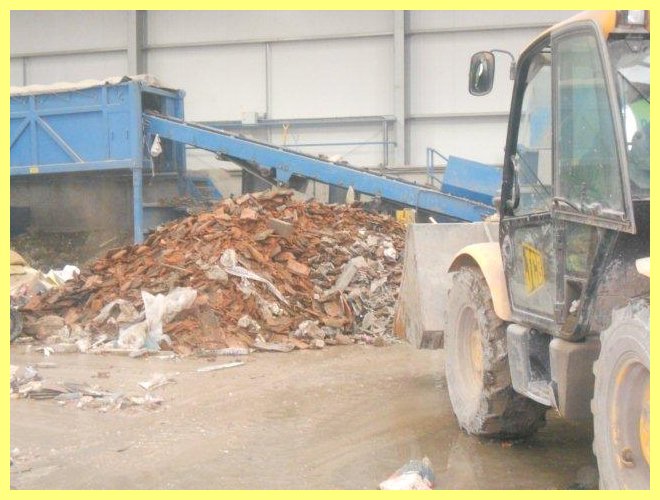

The big digger scoops up waste and dumps it onto a conveyor belt to be sorted. The large blue machine 'shakes' the conveyor belt to get rid of very small 'bits'. A huge magnet then collects all the magnetic waste and the rest is sorted by hand. The finished result is 'clean' rubble which is then used in the building trade.

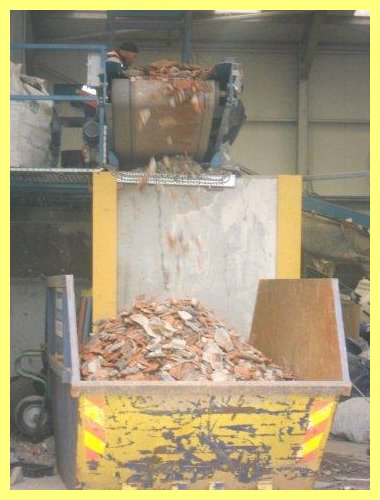

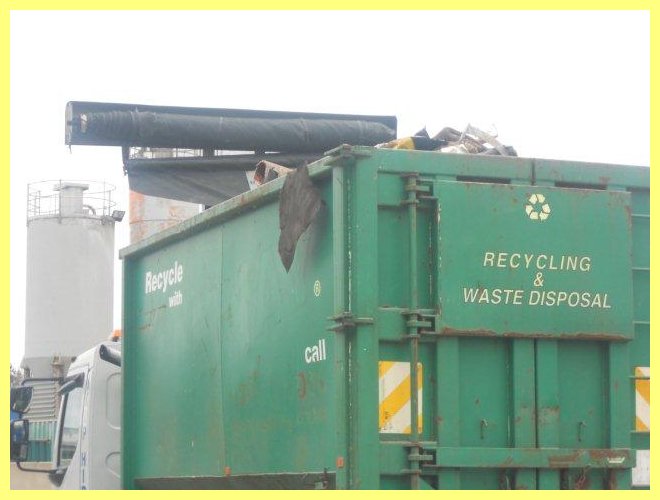

The little digger sorts out things that are too big to go on the conveyor belt and things that can't be recycled. These are then loaded into a skip on the back of a wagon. A net is placed over the top and it is then transported to the local landfill site, only 3% of waste from Derwent Recycling is sent to landfill, that means that 97% of waste that makes its way to the site is recycled to be made into new products.

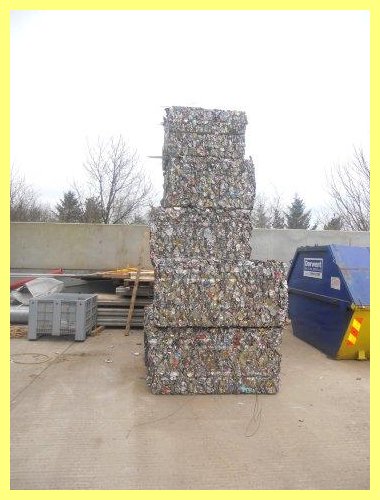

Tin and aluminium cans are recycled into tin and aluminium sheet then manufactured into tins and cans all over again; this is called a recycling loop, and can happen many times!

A big thank you to Mr Farrington and all his staff for making us feel so welcome. :-)